We got back from the road trip nearly 3 weeks ago, and I’ve been so busy getting ready for our journey south to Mexico that I’ve not managed to even finish the story…

The last few miles in from Yosemite were familiar territory, but looking so, so dry. Leaving the mountains, we drove past a wildfire that looked like it had recently started – flames by the side of the road, and a few police cars arriving. We pulled into a lay-by a bit further down the road to see what was going on, as a bulldozer on a low-loader thundered past, sirens screaming. They had a spotter plane circling overhead, a helicopter picking up water from the nearby reservoir, and a couple of planes doing circles dropping red fire retardent powder. Checking back on the internet a few days later, it looked like they got this one under control quickly enough.

10,622 miles and 3 months later, we arrived back in Alameda. What an epic trip. The van held together, we adjusted to living in a micro space, didn’t bite each other’s heads off, and we saw an incredible amount of America. People always ask “what was your favourite part?” – I think it was the intensity of newness. New places, new scenery, constant change, different camp spots each night. Not one bit of boredom or dull routine in all the time we were away. The landscapes were stunning. The mountain biking, especially in the last few weeks, was awesome. Adjusting to being away from full time work was wonderful. The sense of freedom to go wherever we wanted, pretty much whenever we wanted, was addictive.

Each time we filled the tank with fuel I did feel that we were being excessively wasteful, driving around just for the sake of driving around to see places, burning up a whole load of petrol and spewing nasties into the air. I reconciled this with the fact that over the past year we’ve hardly consumed anything in terms of fuel, electricity or waste – living aboard the boat enforces that. And looking into the future, the wind will be our fuel, and the sun via our solar panels will power pretty much everything else.

We’re not sticking around the bay area, we’re going to get moving again. We live on a sailing boat. It’s built to be taken over distant horizons, carrying a crew of excited adventurers, not tied to a dock in a city, getting all dusty and grimy. I’ve always wanted to spend time seeing new lands from the sea, experiencing things that you’d just never experience as a tourist just passing through. But work is also calling… right now I’m on the way to SFO airport, going to spend a week in the UK company HQ with the tech team planning the next few months so I can continue to contribute while being out of the office. Our satellite phone turned up last week and I’m in the process of sorting out an airtime contract, so we should be able to stay in touch wherever we are.

The van is now delivering beer around the east bay; sold to a chef who’s just started a brewery. It felt strange to see it go, having had so much time in it over the summer. It was a home, a shelter from the sun and the rain, our life support machine, our transport and our one piece of consistency in a constantly changing few months. I sold my road bike. We’ve dropped a few bags of winter clothes, and my snowboard, at a buddy’s place (thanks!). Won’t be needing that in the tropics.

Even though I’ve been working steadily away on boat projects throughout the last year, there’s still been a lot to do. In the last couple of weeks we’ve:

- Installed a watermaker to turn seawater into nice clean drinking water. At 3 gallons an hour it’s hardly going to match the flow of Niagara, but it should keep our tanks topped up and allow us to have freshwater showers.

- Replaced all the stinky toilet hoses and pump so the boat now smells all fresh. A job that was surprisingly not as nasty as I thought it was going to be. The hardest thing was making sure I had all the right parts before I started, sine we use the heads on a daily basis.

- Added an electric macerator pump to empty the holding tank when we’re out at sea. The local consignment store is very handy for picking up things like pumps second hand at good prices.

- Spent hours and hours sorting out lockers and belongings down below.

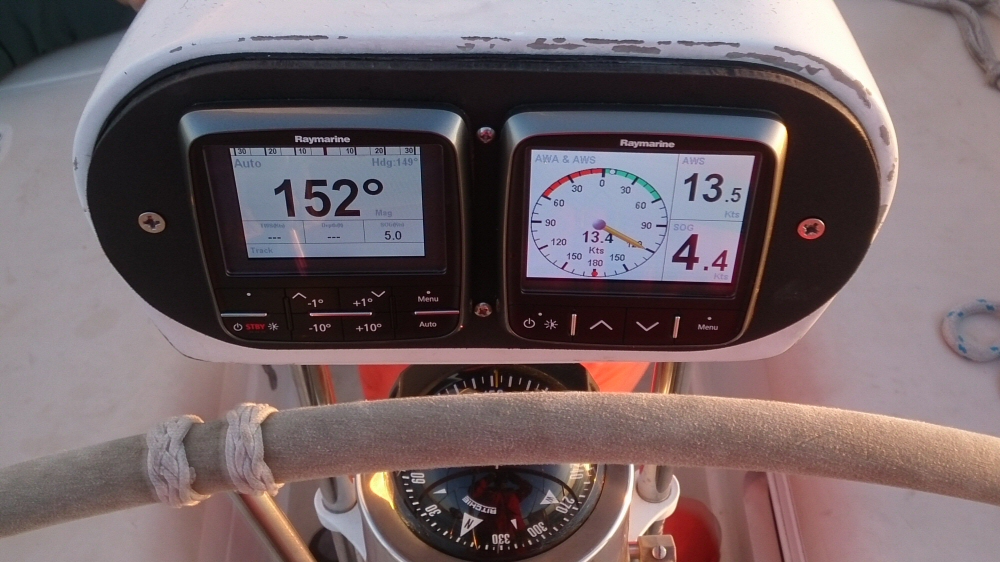

- Fitted an AIS unit so that ships and commercial fishing boats can see us on their instruments, and so that we can see them, even if it’s dark, foggy or stormy.

- Rewired a bunch of stuff, fitted cabin cooling fans and a couple of new lights.

- Made a drink holder for the cockpit so we have somewhere safe to put things when the boat is rolling around.

- Replaced the masthead tricolour and anchor lights with LED bulbs to save loads of power.

- Fixed the top rudder bearing which was starting to loosen. I hope it’s fixed, anyway – we’ve not had the boat out for a sail yet.

- Tightened the steering cables around the rudder quadrant.

- Painted the last 5 metres of the anchor chain red so that we can stop the windlass in time and not lose the whole lot overboard.

- Had both main sail and jib repaired, with a third reef added to the main for super windy conditions.

- Put the name on the stern (ssh don’t tell Neptune, we’ve not had our naming ceremony yet)

- Added flag halyards for our Mexico courtesy flag.

- Stocked up on boat and engine spares.

- Picked up a new outboard engine and ordered a new dinghy. Decided to go with a hard dinghy that converts into a life raft.

- Added an extra cockpit winch to haul in the jib furling line in strong winds.

- Mounted an extra propane tank to the stern for our BBQ/grill.

… plus a bunch more small stuff.

Just 3 weeks to departure! We’re mentally ready – excited of course, and also a bit apprehensive – we’re going to be learning a huge amount in the next few weeks. We met a couple of Brazilians in the marina next door that are fitting out their boat to sail down to Patagonia where they’ll be climbing – they’ll be sailing down the California and Mexico coast about the same time as us. And there will be loads of other people we meet on the way too.

A couple of days ago, when we still had the rental car, we spent the entire day shopping for food. The Big Provisioning Run. Somehow the boat has managed to soak up hundreds of tins, pasta, rice, sauces, jars and a load of UHT almond milk which we may not be able to get once south of the border. That’s all gone under a screwed-down floor panel in the galley. I’ve been trying to stow everything as far aft as possible; ever since we added the new anchor, windlass and chain, Rafiki has been bow-down by a couple of inches. Not ideal, but not much we can do about that. Just before we go we’ll stock up on fresh food. We’ll be near shops pretty often – it’s not like we’re crossing an ocean – but from here forwards everything we buy will most likely need to be ferried out to the anchored boat by dinghy, so it pays to get the bulky and heavy stuff on board while we’re at dock.

Can’t wait!