When I bought this boat, it was pretty much exactly as it came out of the factory nearly 30 years ago. Everything had been looked after, a few things had been replaced, but that’s about it. Because it was built as a “coastal cruiser”, designed for day trips and the odd weekend here and there, it came with a pretty basic 12v DC electrical system.

For extended periods away from shore power, the batteries weren’t going to last long. Perhaps 24 hours at most. And then when it came to charging them up again, the poxy 35 Amp alternator with no fancy regulation would have taken perhaps 7 hours to charge them up again. No es bueno. We’re planning to get a long way from shore power, for long periods of time. Over the past few weeks (months?!) I’ve been reading all I can get on 12v boat systems, and have come up with a new systems design; the two main components being a new, powerful alternator with smart regulator and a set of solar panels.

The new 125 Amp alternator will pack way more of a punch than the old one, the smart regulator pumps the charge into the batteries way faster, and then handles things nicely when the batteries get near full. Budget doesn’t yet stretch to solar AND wind power, so out of the two I decided that we’re going to get more benefit from 200 Watts of solar panels than a wind generator. I’ll mount the panels on the cage I’ve fashioned on the stern rail from the old dodger frame, which just happens to be a perfect fit. They’ll also give a load of shade above the helm for those hot, tropical passages and days sat at anchor…

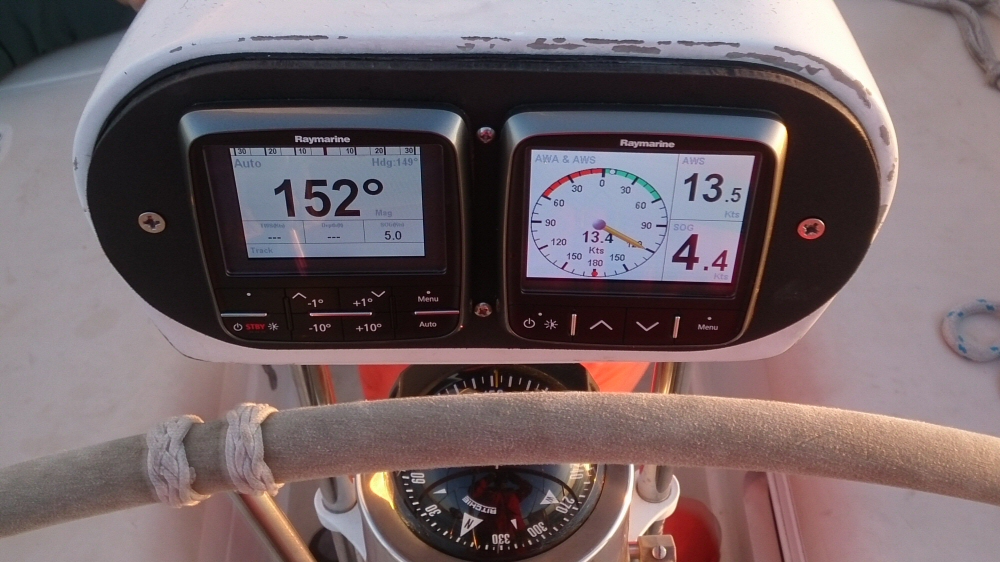

The solar panels are sat by my desk at work waiting for an opportunity for me to swing into the city with the van and pick them up. The other stuff should arrive next week, but I’ve managed to get a few things ready ahead of time. I bought a small car battery to use as the starting battery, which means I can wire the two existing large deep-cycle batteries in parallel and double the useful capacity for everything else – the fridge, lights, autopilot, instruments … so we’ve about 230 Amp-hours there now. From my workings we’ll be using about 100 Ah per day whilst on passage with all the gubbins on and lights at night, so even with the panels giving full power for about 6 sunny hours we’ll still need to run the engine every day to keep the batteries healthy. At anchor when we’re not using navigation lights and autopilot, the solar panels should keep at least the fridge running.

I found a space for the starting battery just next to the existing battery bank, nestled in between the side of a drawer and the fuel tank. I built a solid box for it and have wired it up. Now we’re all set for the solar panels and the new alternator. The panels are going to be run via an MPPT controller, which does some smart jiggery-pokery with the Amps and Volts from the panels to make sure that they are operating at their most efficient.

We’re still going to be on the dock here for a while yet … so why the need to get all this stuff? I want to have plenty of time living aboard self-sufficiently before we cast off the dock lines and set sail over the horizon. If something’s not quite right, I can get it sorted now whilst there’s plenty of stores and services around. And I also want to see if we can go “off-grid” completely, even while we’re here. We only use the mains power to top-up the batteries, and for a bit of heating. I’m hoping that with spring on the way, we’ll leave the heater off and run everything off solar power.

A month or so ago I installed a voltage / current meter in the dashboard so I can see exactly what load we’re using. The biggest drain is the fridge, which takes about 7 Amps for perhaps 20 minutes each hour. That’s 8 hours * 7 Amps each day … 56 Ah. The solar panels will output 10 Amps at max power, perhaps for 6 hours a day … the 60 Ah just covering our bases. We’ll see!